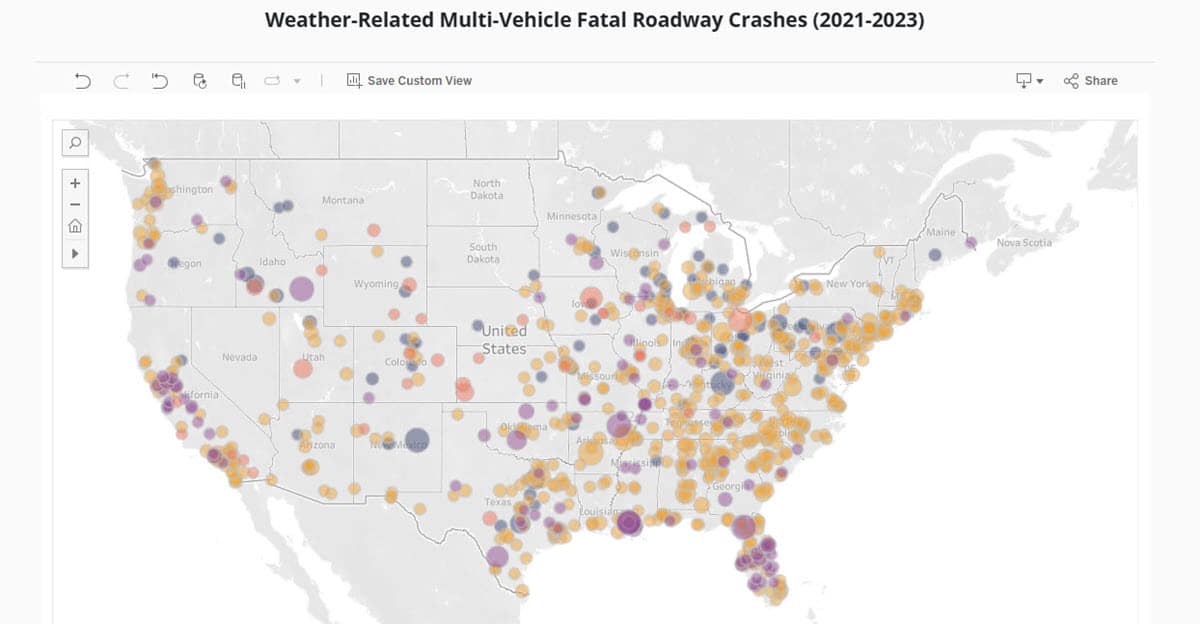

Weather-Related Collisions are Preventable

Every year, thousands of commercial trucks are involved in collisions caused or influenced by adverse weather conditions – rain, snow, ice, fog, or high winds. While the weather may appear to be the primary culprit, the harsh truth is that many of these incidents are preventable.

With proper preparation, equipment, and driver training, fleets can significantly reduce the likelihood of weather-related accidents. By improving safety and operational affordability, carriers place themselves in a stronger position to manage risk responsibly.

The True Cost of Weather-Related Collisions

The visible aftermath of a collision—damaged equipment and stranded cargo—is only a fraction of the total impact. Behind every weather-related crash lies a cascade of hidden costs: repair bills, cargo losses, environmental cleanup, injury claims, fatalities, and often, the loss of customer trust. Understanding the true cost of these preventable accidents underscores why proactive safety management is not just a compliance requirement but a financial necessity for improving safety and operational affordability across fleet operations.

1. Truck Repair and Downtime

A single slide on an icy curve or a hydroplaning event during heavy rain can cause extensive vehicle damage. Even at moderate speeds, loss of traction can lead to jackknifing, rollovers, or collisions with roadside barriers and other vehicles.

Modern commercial trucks are outfitted with complex electronic systems like collision sensors, lane-keeping cameras, and adaptive cruise controls. All are costly to repair or recalibrate after impact. While insurance may cover some damage, deductibles, downtime, and secondary expenses often fall directly on the carrier.

The larger cost, however, is operational downtime. A truck out of service for weeks means lost revenue from missed loads, delayed contracts, and administrative time spent coordinating repairs and replacements. During peak seasons, one disabled vehicle can disrupt an entire dispatch schedule. These preventable disruptions undermine both productivity and operational affordability, creating long-term financial strain.

2. Lost or Damaged Cargo

In weather-related crashes, cargo losses are common. A trailer that overturns on a wet or icy highway may suffer punctures, moisture exposure, or complete destruction of contents. Refrigerated units can fail if power is interrupted, and temperature-sensitive goods like flowers, pharmaceuticals, or produce can be lost within hours.

A single load of flowers or fresh food can be worth over $100,000. For time-critical shipments, the financial loss compounds: not only must the carrier reimburse the shipper, but the customer may also incur downstream losses in their own supply chain.

Even when cargo is insured, claims take time to process. Meanwhile, the fleet must manage damaged-goods documentation, coordinate salvage, and face strained customer relationships – all while trucks sit idle.

Carriers that implement stronger weather-related safety practices protect both revenue and improving safety and operational affordability, reducing costly cargo disruptions.

3. Roadside Cleanup and Environmental Liability

Weather-related accidents can make cleanup efforts particularly hazardous and expensive. When a truck loses control in rain or snow and spills fuel, oil, or hazardous materials, cleanup crews must operate under poor visibility and dangerous road conditions.

Containment and environmental remediation costs escalate quickly, particularly if runoff contaminates soil or waterways. Specialized hazmat teams, protective gear, and disposal services can push expenses well into the tens of thousands of dollars.

Even non-hazardous loads such as consumer goods, produce, or building materials require debris removal and coordination with law enforcement and state environmental agencies. In these cases, the carrier typically bears financial responsibility, adding yet another unplanned expense to an already costly event.

By reducing preventable accidents, carriers protect the environment, maintain compliance, and contribute to improving safety and operational affordability by avoiding fees, penalties, and cleanup costs.

Calculate My ROI for Critical Weather Accident Prevention

4. Roadside Cargo Transfer and Logistics Disruption

After a weather-related accident, the damaged truck is rarely able to continue its journey. To salvage the shipment, the cargo often needs to be transferred at the scene or at a nearby staging area to another truck.

This process can be logistically complex, particularly in harsh weather conditions. Specialized lifting or transfer equipment, additional personnel, and replacement vehicles are required. Every hour of delay risks further cargo damage, missed delivery windows, and penalties under contractual service agreements.

Dispatchers must juggle route changes, secure an available replacement truck, and coordinate driver schedules—all while managing safety concerns in adverse weather zones. The resulting inefficiencies can ripple through fleet operations for days or weeks, compromising both service reliability and operational affordability.

5. Loss of Cargo Value and Customer Relationships

Weather-related accidents don’t just destroy cargo; they can destroy trust. When a customer’s goods are delayed or damaged due to a preventable collision, confidence in the carrier’s reliability erodes.

Many clients operate on just-in-time inventory systems, where a single missed delivery can halt production lines or lead to missed retail opportunities. A flower distributor missing a Valentine’s Day delivery or a food supplier failing to restock a grocery chain loses not just revenue but reputation.

Even if the weather is to blame, customers often perceive the issue as a failure in risk management. They expect professional carriers to plan ahead, monitor forecasts, and make the judgment call to delay or reroute when conditions deteriorate.

One preventable mistake can result in the permanent loss of a valued account. Protecting customer relationships is essential to long-term profitability and improving safety and operational affordability within fleet operations.

6. Driver Injury and Workers’ Compensation

Adverse weather is one of the leading causes of truck driver injuries. Loss of control, jackknifing, or rollovers on slick surfaces can result in serious harm. Beyond the human toll, these injuries trigger costly workers’ compensation claims, medical bills, and legal exposure.

Carriers must also absorb the cost of lost productivity and administrative time managing claims. If the injury leads to long-term disability or the driver’s inability to return to work, replacement costs multiply.

Even when drivers recover, post-incident trauma or fear of similar conditions can affect performance, leading to more cautious driving behaviors that slow routes and affect delivery efficiency. Investing in weather-related training, pre-trip planning, and preventive safety technologies enhances driver well-being while supporting improving safety and operational affordability, helping fleets better manage workforce-related costs.

7. Recruitment, Training, and Replacement Costs

If a driver is injured or decides to leave after a collision, replacing them is costly. Recruiting qualified CDL drivers is already a challenge across the industry. The process of screening, onboarding, and training new hires adds thousands of dollars in expenses and weeks of lost productivity.

Moreover, preventable weather-related crashes can harm a company’s reputation among drivers. Word travels fast in the industry. If drivers perceive a fleet as one that pressures them to drive in unsafe weather or fails to support them with proper safety policies, recruitment and retention suffer.

The long-term impact is a decline in morale and trust—two factors critical to maintaining a strong safety culture and operational affordability.

8. The Cost of Sending a Second Truck

When a truck is immobilized due to a weather-related collision, the fleet must often dispatch another unit to complete the delivery. The second truck incurs costs for fuel, driver wages, wear and tear, and potential overtime pay.

Additionally, this unplanned dispatch can throw off scheduled routes for other deliveries, forcing the carrier to rearrange logistics across multiple loads. For smaller fleets with limited equipment, this disruption can be especially damaging, diverting scarce assets from profitable routes.

In many cases, the cost of deploying a second truck to rescue a compromised shipment exceeds the profit margin of the original load—turning a routine haul into a financial loss.

9. The Hidden Costs: Insurance, Safety Scores, and Reputation

A single weather-related collision—even one deemed “minor”—can have long-lasting financial repercussions. Insurance premiums often rise following claims, and the fleet’s Compliance, Safety, Accountability (CSA) scores may take a hit. Poor CSA scores can deter shippers, limit business opportunities, and make future insurance renewals more expensive.

Furthermore, regulators and insurers increasingly view weather-related collisions through the lens of preventability. If it is determined that the driver could have slowed down, adjusted routes, or delayed the trip, the carrier may bear additional liability.

The reputational damage can be even greater. Customers expect professional carriers to exercise judgment and prioritize safety, even when that means delaying delivery. A preventable weather-related crash signals a failure in planning and risk management—a perception that can take years to rebuild.

10. Prevention as a Profit Strategy

When you total the costs—repairs, cargo loss, cleanup, injury claims, insurance hikes, and lost business—a preventable weather-related collision can easily exceed several hundred thousand dollars. The good news is that most of these incidents are avoidable.

Investing in weather-focused safety measures yields measurable returns. These include:

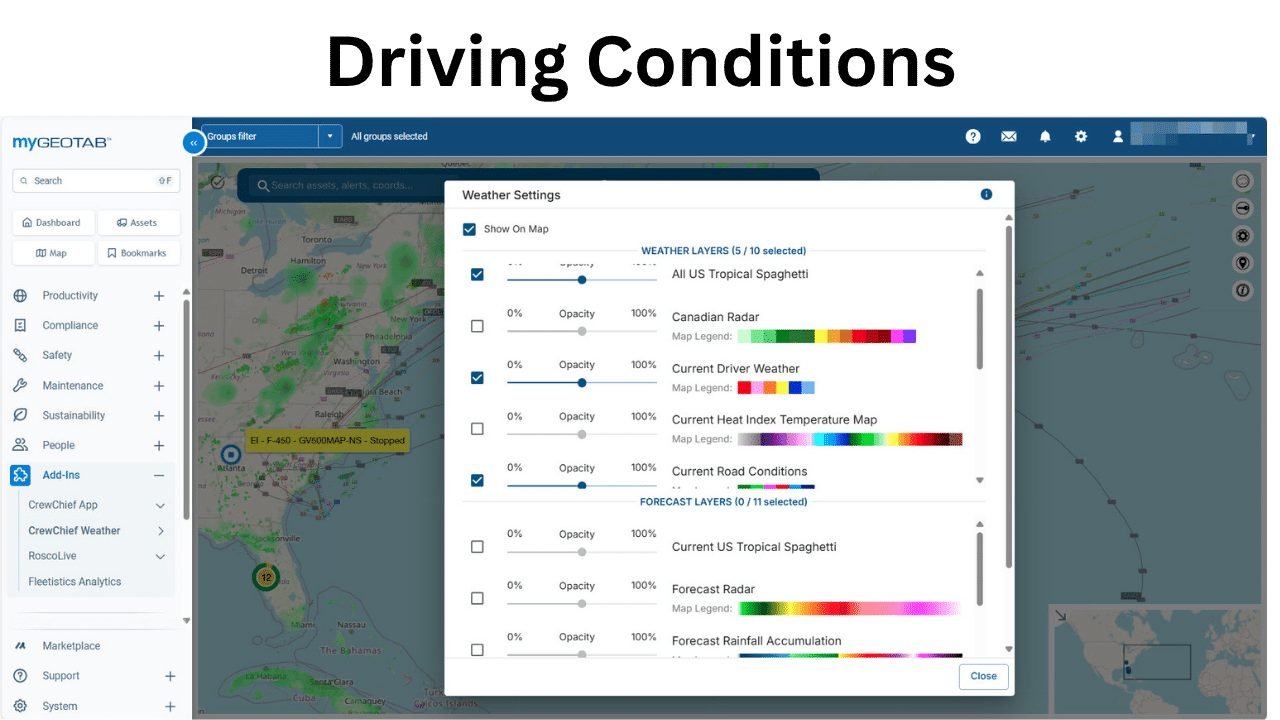

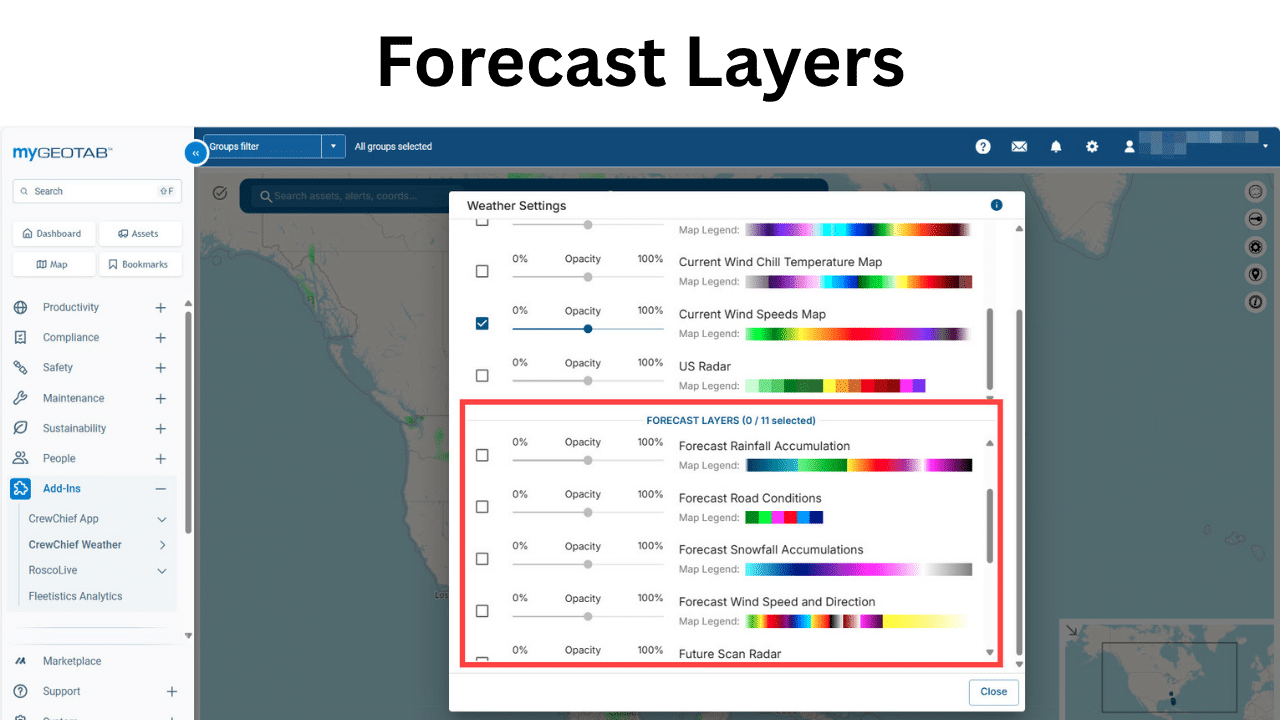

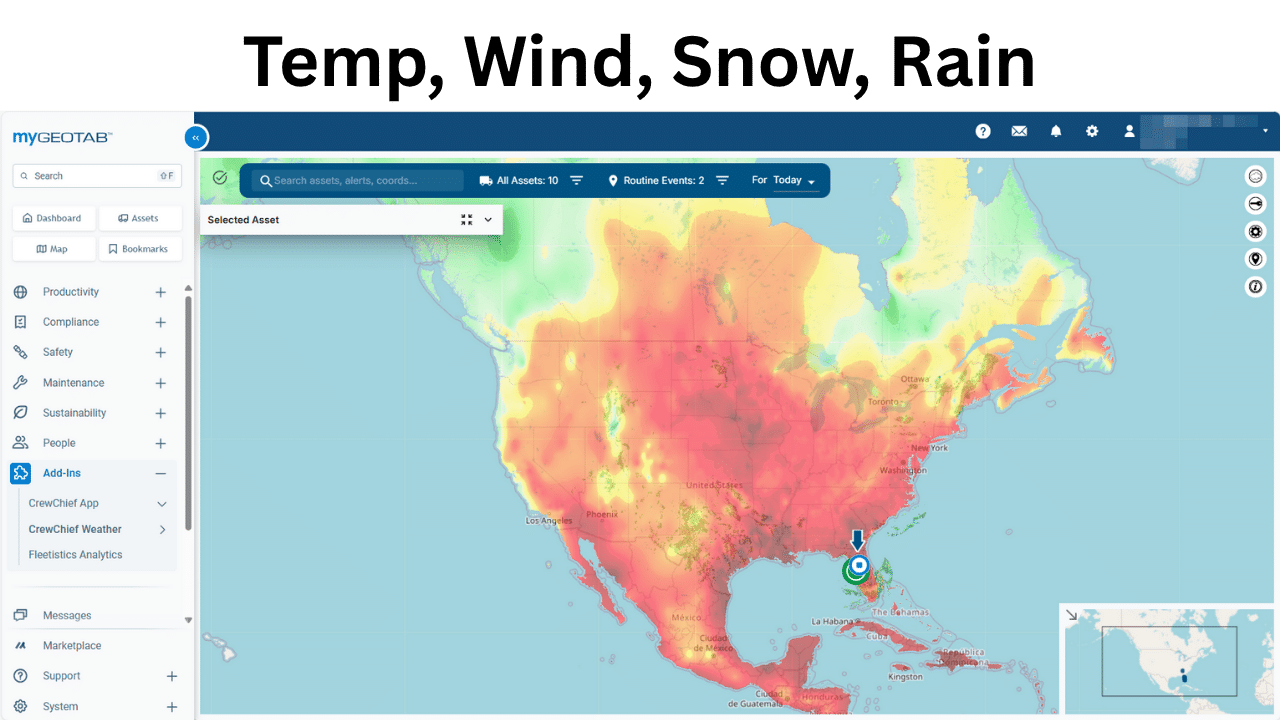

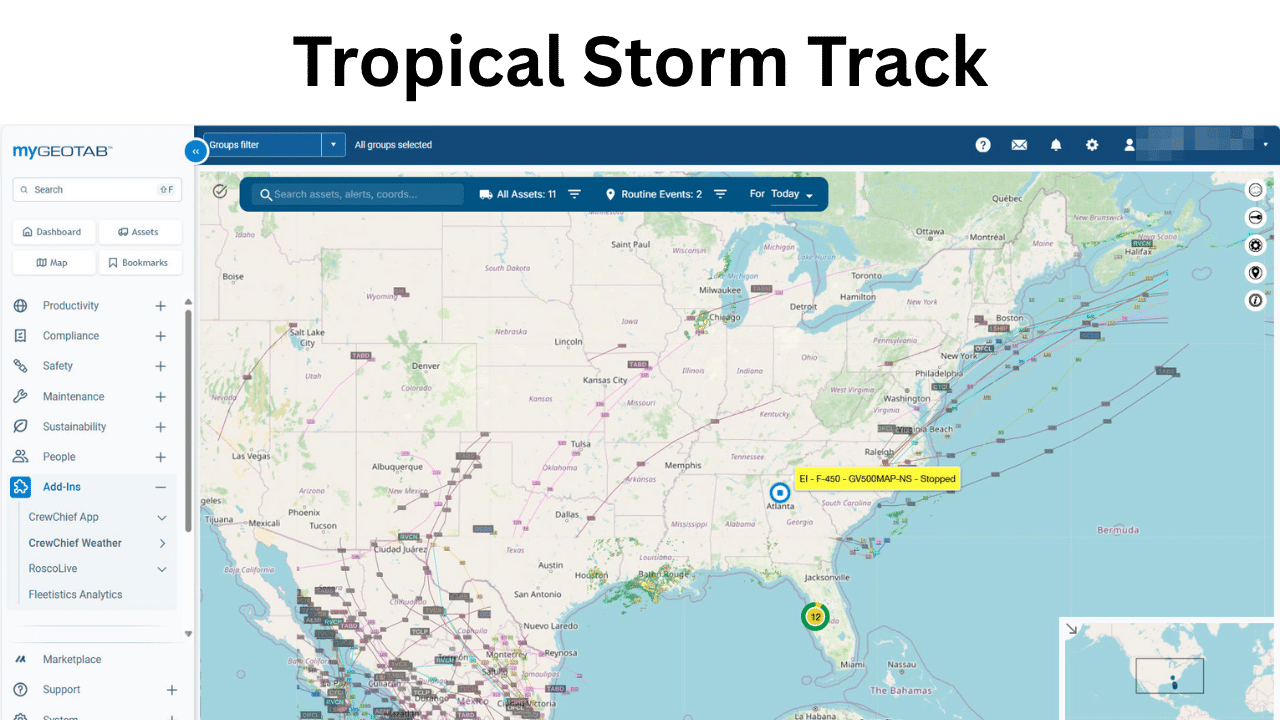

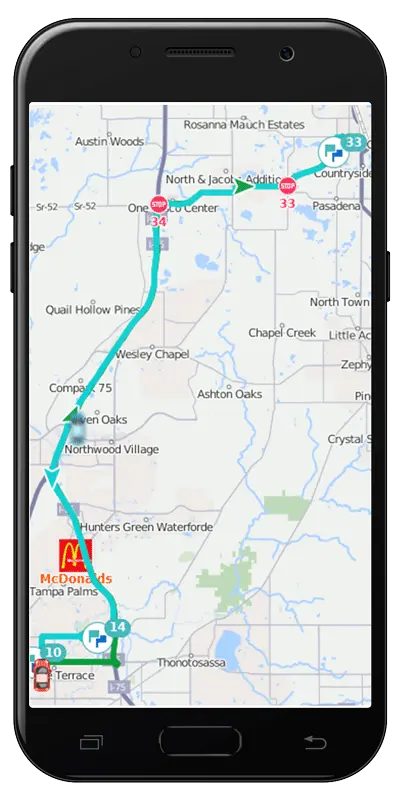

- Real-time weather monitoring systems integrated into dispatch and routing software.

- Driver training focused on recognizing and responding to hazardous weather conditions.

- Fleet policies that empower drivers to delay or suspend trips without penalty when conditions become unsafe.

- Equipment investments such as advanced traction tires, automatic braking systems, and adaptive cruise controls.

- Predictive analytics to identify routes or regions with high weather-related incident frequency.

By proactively managing weather risks, carriers can protect both their drivers and their bottom line. Safety isn’t just a compliance box to check—it’s a financial strategy that prevents cascading losses across every layer of the business.

Get Critical Weather Tools to Impact Safety, Efficiency, Liability, and Operational Affordability

Weather is the leading factor influencing both the timeliness and safety of product and service delivery. By integrating real-time weather intelligence with your location data, dispatchers gain the ability to make informed, immediate decisions that were previously unattainable. These enhanced decisions strengthen operational safety and improve overall profitability. With CrewChief Critical Weather, stronger decisions start at the source.

CrewChief Critical Weather is available on the Geotab Marketplace. Use the “Order Now” button for a seamless installation and integration into your Geotab database.

Calculate My ROI for Critical Weather Accident Prevention

Conclusion: Tools of the Trade

A preventable weather-related truck collision is more than an unfortunate accident—it is a costly failure in preparation and decision-making. From vehicle repairs and cargo loss to insurance penalties and damaged customer relationships, the financial toll extends far beyond the crash site.

Fleets that invest in weather awareness, driver education, and strong safety culture see fewer incidents, lower operating costs, and stronger customer loyalty. In an industry where reliability defines reputation, the ability to anticipate and adapt to the weather isn’t just smart—it’s essential.

When the next storm rolls in, the question isn’t whether your fleet can handle the weather—it’s whether you’ve prepared well enough to avoid becoming part of its aftermath.