Cost Savings – Where will you find them?

In this part of our Return on Investment series, we will discuss specific telematics related cost savings categories that compile our Fleet Savings Summary Report.

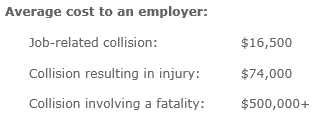

#1 Safety: Reducing costly vehicle collisions

The U.S. Occupational Health & Safety Administration (OSHA) reports thefigures above.

Collisions, speeding, and aggressive driving behaviors were found to be a contributing factor in 31% of all fatal crashes, while seat belt use was found to decrease the risk of a fatality by between 45-60%. With this knowledge and the use of our telematics program, fleet managers can improve profitability by monitoring driver behaviors and proactively coaching drivers.

Other in-cab driver feedback tools such as GO TALK and real-time audible alerts can drastically reduce the likelihood of an on-duty accident. This can also be quantified in a reduction to insurance costs. To quantify these savings, the Fleet Savings Summary Report uses a proprietary safety-scoring algorithm to determine the existing and potential savings for a fleet.

#2 Fuel: Controlling Runaway Fuel Cost Savings

Managing fuel costs can be complicated and involve a number of variable, including fluctuating gas prices and inconsistent driver behavior. For many fleets, fuel is one for the largest expenses.

Fact: The U.S. Department of Energy reports that rapid acceleration and heavy braking can reduce fuel economy by up to 33% for highway driving and 5% on city roads. Idling and speeding can also have drastic impacts on MPG.

Market research has shown that the effective use of telematics has an effect on fuel cost savings by as much as 14%. Driver coaching is instrumental in achieving these cost reductions. For every 5 mph over 50 mph, a driver can reduce their MPG by approximately 7-14%. Therefore, getting drivers to slow down and observe the speed limit translates into saved money.

The Fleet Savings Summary Reports uses a proprietary fuel-scoring algorithm to determine a fleets existing and potential fuel-related savings. In doing so, driver speeding incidents and idle time were found to be the largest contributor to fuel waste, which resulted in fuel-related savings.

#3 Maintenance: Reducing Planned and Unplanned Repair and Maintenance

We all know that preventative maintenance is a regular part of owning a vehicle, but additional repairs due to aggressive driving and vehicle misuses are an unnecessary cost to a fleet. Particularly, harsh accelerations, harsh cornering, and harsh braking cause harmful wear and tear on critical vehicle components. This drastically increases a vehicles variable CpM.

The results materialize as reduced tire life, reduced brake life, more frequent scheduled maintenance and more frequent non- scheduled maintenance and repair. In fact, these non-scheduled maintenance interruptions can result in lost profits of between $400 to $700 per day, in addition to the cost of repairs.

The Organization for Economic Co-operation and Development (OECD) reports that telematics technology can help a company reduce maintenance and repair cost by as much as 14%. Because much of these savings are tied to driver behavior, using real-time driver management tools and in-cab alerts are the best way to minimize unnecessary wear and tear on your fleet vehicles.

By managing the aggressive driving behaviors, fleet managers can minimize their maintenance repair costs, in in turn generate savings reflected in the Fleet Savings Summary Report in the Maintenance section.

#4 Productivity: Increasing Work Efficiency

Driver compensation is often a large portion of a fleets operating budget. That being said, labor can be very expensive for fleet managers. Among the many ways to calculate labor productivity, vehicle idle time is an important metric. Even though idle time only captures a component of employee productivity, it is the only metric that the Fleet Savings Summary Report utilizes for its productivity-based scoring algorithm at this time.

Market research suggests that telematics can increase workforce productivity and reduce labor costs by up to 12%.14 This allows companies to make more customer stops and cut out unproductive mileage. The net effect is higher revenues and lower costs.

Using the Fleet Savings Summary Reports proprietary productivity-based scoring algorithm, this increase in workforce productivity translates into productivity-related saving. To maximize these savings, fleet managers must limit their fleets idle labor, which is approximated using vehicle idle hours per trip.

Contact us today to request more information.