Top Considerations When Selecting an Asset Tracker

Understanding the features, cost and communication method is essential to selecting an asset tracker. Asset trackers vary features and one key feature might dramatically improve your ROI. The first step to getting it right is to make a list of the features you must have and the features you would like to have. Find asset trackers that have the “must have” features and work from there. Getting everything in writing and demonstrated is also important. Your concept of a feature might very different from that of the sales rep.

Getting What You Need, Will Save You Money

There are several things to consider when investing in a GPS system to track assets. Thinking through these factors will ensure you make the right choice. You will notice that price is not a consideration listed. When dealing with $250,000+ equipment or $10,000 utility carts, the price difference between a $200 asset tracker and a $400 asset tracker is irrelevant if you get what you need.

Rugged Construction

Obviously, the environment for tracking heavy equipment is quite harsh on electronics. At a minimum, you want an IP-67 rating. Asset trackers should least be weatherproof, dust proof and designed to handle the high vibration found on equipment. Few units are designed to withstand pressure washing from less than 3 feet. When selecting an asset tracker get the technical specification sheet available for all devices. View GO Rugged

Backup Battery

A common feature requested is a backup battery. A backup battery can play a key role but batteries have limitations ranging from a last gasp transmission to a reduced reporting profile so the battery can last longer if the main power is disconnected. Get a clear understanding of the battery size and expected performance so you can make a good decision. Selecting an asset tracker without a backup battery means the device must always have power to function. If constant power is an issue, focus on the size of the battery and how the device performs when running on battery power.

Right Data

Ultimately the selecting an asset tracker means getting the data YOU need, not what the sales rep wants to sell you. Having a clear understanding of what is required from the data and what data you would like to have before you shop for an equipment tracking system will make your buying process more efficient.

It is important to keep the list of required data as short as possible. The more required data, the fewer your choices. If engine hours are required, almost any equipment tracker will work. If you need engine diagnostics codes from a CAT, Komatsu, Case, John Deere or Bobcat, the choices are very limited and often expensive relative to less capable asset tracking systems.

Equipment tracking might be part of a bigger fleet management program. Therefore, the data provided by the equipment tracker may need to look like vehicle tracking data and be in the same interface. A system like the GO System enables fleet managers to see similar data, in the same interface and set the same alerts and reports. This convenience saves time in more complex fleet environments. If the requirements are simple and static, an independent system which is lower in cost might do the trick.

GO RUGGED WORKS WITH GEOTAB’S GO SYSTEM AS AN INTEGRATED FLEET MANAGEMENT PLATFORM – More About Tracking Heavy Equipment

Sample Asset Tracker Requirements:

- IP67 rated for durability

- Backup battery to aid in theft recovery

- Location data to indicated productivity and aid in theft recovery

- GPS position every 10 minutes when in motion to indicate productivity

- GPS position every 24 hours when ignition is off for inventory & field service

- Tow alert movement without ignition, indicating theft

- Zone violation alert between 8 pm and 6 am Monday Sunday

- Engine hours for routine maintenance and tracking billable hours

Installing Asset Trackers

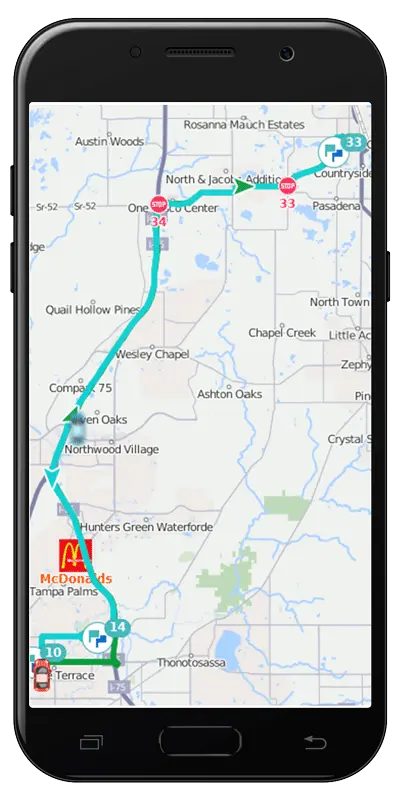

Installing an asset tracker or equipment tracker can be a challenge or as simple as slapping it on the top, depending on your intended use. The type of material and angle have a lot to do with getting good GPS location information. GPS trackers have a directional antenna and facing the antenna toward the ground or putting up against the metal frame will degrade the GPS signal. For instance, putting the GPS unit in the engine compartment is often not going to work.

As an anti-theft device you would want to place it in a location that is not obvious. The challenge is that where you want to hide it, it may not get a GPS signal. GPS signals are blocked by metal so be sure to test the location before putting everything back together. One idea is to put the GPS device in the light housing. Customers have purchase amber light housings on eBay for $20 and hid the GPS inside.

Put the GPS system in a location where it is not likely to get pressure washed. The driver is not going to know or pay attention to the IP67 limitation (debris and moisture rating) of not pressure washing from less than 3 feet. The driver might accidentally wash it from 1 foot forcing water into the unit which will not be covered by warranty.

Protect the connections by soldering the connections and then putting heat shrink tubing over the connections. Ideally the connections are out of the line of fire of pressure washing. You may need to build a shield or put the unit and connections behind something to protect it.

If have a need to track heavy equipment (yellow iron), skid steers, ATV, utility carts, trailers, train cars, cargo containers, generators, boats, motorcycles or just about anything, contact Fleetistics. With 16+ years of asset and vehicle tracking experience, Fleetistics provides a complete line of solutions to meet your needs. 855-300-0527