Multitasking Is The New Normal

In 2020 there was a huge shift in the way we do business. We were multitasking before, but often in a community workspace with more team interaction. Social distancing has forced us to re-think the workspace and work more independently. With that comes more multitasking, and a new level of stress and confusion can emerge. For drivers who have more technology to manage on the road, mistakes can have deadly consequences.

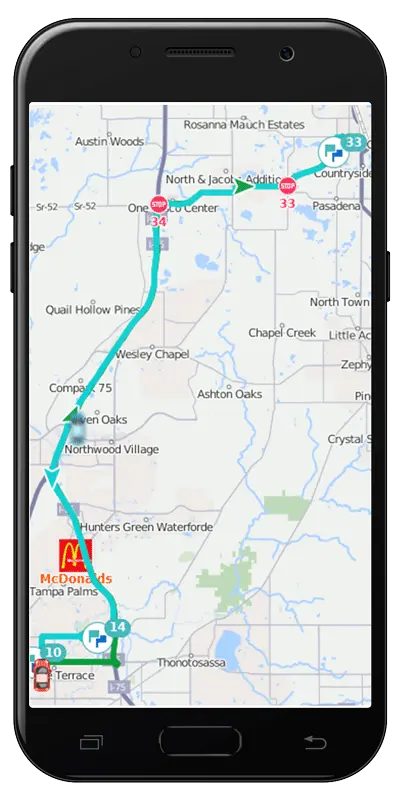

Fleets are using more electronics than ever for navigation, ELD, work orders, and communication. Fleet managers supervise drivers engaging in potentially dangerous multitasking that in some cases runs counter to the safety programs in place. Managers and dispatchers make exceptions when they need something, but later hold a driver accountable for talking on a phone while driving. Is there a double standard? Where do operational requirements supersede safety best practices? It’s an uncomfortable conversation, but one we need to be having.

Applying Wisdom From Other Disciplines

As a training center for NSC’s Defensive Driving Course, we used to get a lot of safety related communications and links to safety related content. A recent article Safety Leadership: Reducing catastrophic incident potential via enhanced human performance reliability by Matt Hargrove from DEKRA Organizational Safety and Reliability caught our attention. His post focuses on catastrophic incidents that occur on offshore drilling rigs, but there was some underlying wisdom that can be universally applied.

Given, most of our readers are not doing potentially life threatening jobs in dangerous environments, but one statement Matt Hargrove made strikes at the heart of what most of us are doing.

“We make more mistakes when our work is designed to have us multitask.”

That statement is true for drivers, managers, support staff, vendors… all of us. And with all of the technology we use day to day, everyone is multitasking. So, how can we support employees to make fewer mistakes while still accomplishing all that needs to be done?

The author listed 5 specific “layers of protection” to be considered to “further reduce potential for catastrophic incidents”. If we consider those same recommendations with a fleet based operation in mind, are able to identify specific actions we can take to prevent the common multitasking related mistakes we make everyday.

Five Layers of Protection

- “Creating clear alignment on prioritization of competing organizational

targets and objectives.”

Make sure drivers, managers, and support staff are clear on their own priorities, and each other’s. A manager that needs something done right now must consider a driver’s first priority is arriving safely. It’s OK to communicate urgency, but not to pressure the driver to hurry unduly. If he is a few minutes late due to driving on icy roads, express that it is OK.

2. “Creating brain-aligned standard operating procedures and documents in which design and content are developed in a way that highlights critical steps and prompts specific actions that reduce potential for critical error.”

Maybe it’s time to take a good look at our forms and processes. Do forms follow the work flow so that drivers and other workers can document what they are doing in the order they normally do it? Are the fields for must have information required fields on electronic forms and highlighted somehow on paper forms? Are you using checklists to confirm the proper steps have been taken?

3. “Creating specific lines of inquiry related to human performance and human-machine interface to understand how errors might occur/or have occurred post-incident.”

When mistakes are made, they should be reviewed to determine why they were made. Take advantage of every opportunity to learn from mistakes and understand if multitasking is contributing to errors made. That responsibility needs to be owned by someone in the organization. Once we identify the common threads when mistakes occur, we can take steps to mitigate their re-occurrence.

4. “Deploying a structured technique for hazard identification (going from looking to seeing and mitigating hazards). Creating prompts that move people out of the default autopilot (fast brain) during safety-critical transitions within work tasks.”

Within our own departments we do things out of habit because that’s the way they have always been done. Perhaps we should get a fresh set of eyes on our procedures and forms to help us identify areas we might improve. For instance, we recently identified that two employees in different departments were both creating and uploading a nearly identical document into the same shared folder. We determined it made more sense to share a single document cutting both workloads. Now, both know to check the folder for an existing document before creating a new one. It’s a small thing, but every little bit helps.

5. “Training frontline team members to understand the causes of performance errors and co-develop the techniques and system changes necessary to control for them.”

This goes hand in hand with #4 on the list. Management needs to be on the lookout to identify wasted effort wherever it lives. It could be anything from an employee spending hours doing something manually that could be done more efficiently with the right software or integration, to identifying overlapping tasks that can be shifted to the most appropriate team member. If we can split the workload we can eliminate some of the multitasking.

A Few Simple Ideas You Can Implement Now

Some suggestions from our own staff include completing the task you are working on before starting another, closing your email client to avoid distractions, and organizing your email inbox with folders to prioritize and group similar tasks together. It all seems to come down to being open to change. There are a plethora of apps designed to help us get more done in less time and with less error. Being willing to evaluate and invest in those new solutions can be a game changer!